Anti-Fingerprint Products

AF anti-fingerprint coating particles

Click to expand +

Products:

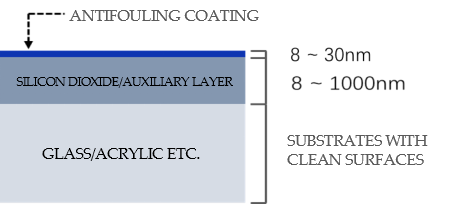

Anti-fingerprint coating granule is a coating product for PVD equipment.

The anti-fingerprint coating particles evaporate the AF components adsorbed in the carrier to the surface of glass or film under vacuum heat to form a hydrophobic and oleophobic nano-scale film layer, which can effectively reduce the adhesion of fingerprints and all kinds of stains, and at the same time improve the product surface resistance to abrasion, UV, salt spray, chemicals, high temperature and high humidity.

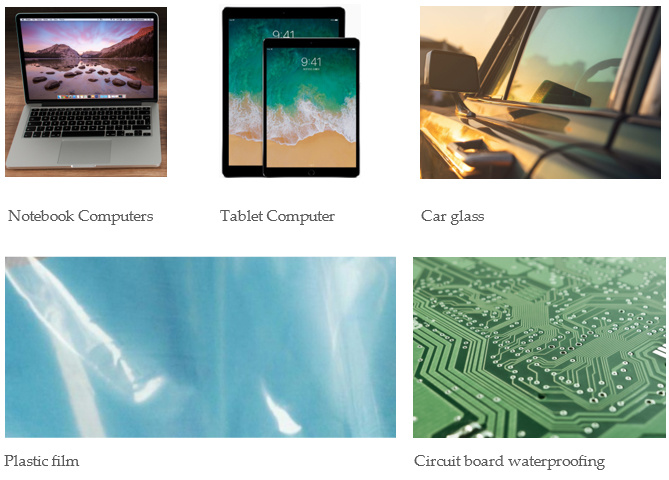

Anti-fingerprint coating particles are mainly used in mobile phones and computer screens, automotive glass, eyeglasses, camera lenses and so on.

Dongxing S/H series anti-fingerprint coating particles is a vacuum thermal evaporation coating product. Different models are customised according to the performance requirements of different customers and the conditions of different vacuum coating machines (chamber size, evaporation method, heating carrier style).

AF Spray Fluid

Click to expand +

Products:

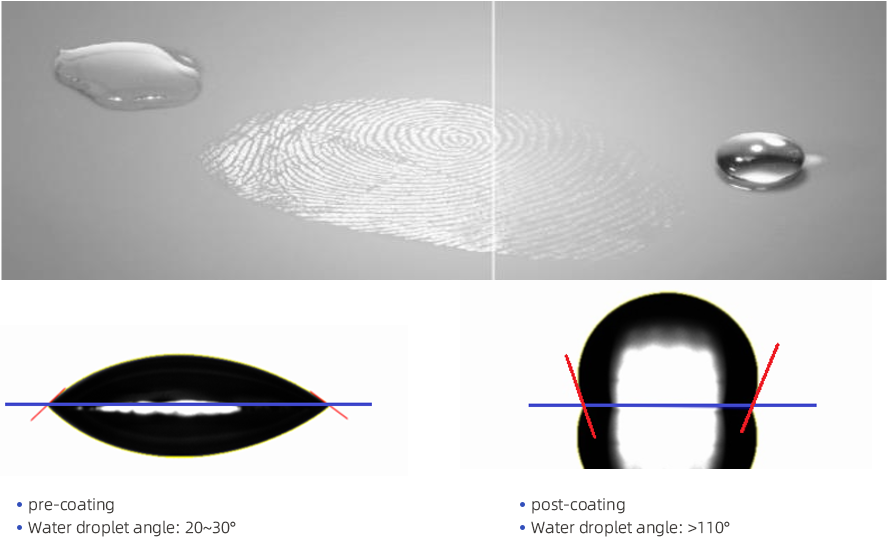

AF Spray Fluid is a wet coating product. It is sprayed to form a hydrophobic and oleophobic nano-scale film layer on the glass surface, which effectively reduces the adhesion of fingerprints and various kinds of stains to provide an easy-to-clean surface coating.

Product Characteristics:

- Excellent water, oil and sweat resistance, easy to clean dirty fingerprints.

- Low coefficient of friction to enhance the smooth touch feeling.

- Transparent nano-film, protects the optical properties and texture of the substrate.

- Forms a chemical bond with the surface of the product to provide high friction resistance.

Spraying process:

Advantages of the spraying process:

- Typical wet process equipment, small footprint, high capacity.

- Single side coating, easy to operate, good film quality.

- Combined with a continuous production line, it can be operated continuously.

- Can be used in assembly line production, glass size can be switched according to the width.

Application scenario:

AF anti-fingerprint main agent

Click to expand +

(Ⅰ)Wear-resistant AF stock solution

Products:

AF Original Fluid is a colourless, odourless and transparent liquid composed of fluorosilicone polymer, which is suitable for antifouling and anti-fingerprint treatment on the surface of high alumina silicon glass, mobile phone glass cover, glass protection sticker, electronic display, optical lens and metal substrate. After treatment, the surface of the substrate forms a complete protective film that is waterproof, anti-fouling and anti-fingerprint, with superior adhesion, very low surface tension, excellent hydrophobicity and oleophobicity, anti-fingerprint, easy to wipe, and high smoothness.

AF Fingerprint Resistant Features

Suitable for a wide range of substrates, with hydrophobic and oleophobic properties, anti-fingerprint adhesion. At the same time, it has the properties of smoothness, salt spray resistance, chemical resistance, high temperature and high humidity resistance, and UV resistance.

- For the film substrate, a unique formula is used to make the anti-fingerprint coating more excellent abrasion and rub resistance, such as wool felt CS-3, CS-5.

- AR + AF process of coating, using a special formula, with excellent adhesion, can withstand steel wool more than 3000 times, eraser 3000 times, in the salt spray and lye and other ring measurement data can also do very good results.

- Anti-fingerprint coating on the surface of metal substrates developed high-performance formulations, excellent performance in salt spray resistance, lye resistance, etc., and successfully developed stainless steel, anodising, electroplating and other areas of coating processing.

- The UV-resistant AF products developed have excellent UV-resistant performance to meet the needs of outdoor use, and can be widely used in the automotive field, photovoltaic field, and outdoor construction field.

Dongxing DX Series Anti-fingerprint Main Agent

- High-end series DXS, the current steel wool can do 30,000 times, eraser can do 8,000 times.

- Mid-range series DXZ, to meet the needs of most customers, the performance of Japan's Daikin, Shin-Etsu and other companies competing products.

- Ultra-low-end field, no-bake anti-fingerprint liquid MK series, construction is extremely simple, in outdoor construction, curtain walls and other areas can be developed and used in bulk.

- Customisable series, Tohko's own derivatives, special products in the field of anti-bacteria, anti-UV, anti-handsweat, etc., can be accepted for development and customisation.

(Ⅱ) Ultraviolet-resistant and anti-fingerprint original fluid UF-310

Product Description:

UV anti-fingerprint liquid UF-310 is a UV aging hydrophobic and oleophobic nano-fingerprint oil, colourless and odourless transparent liquid for glass, metal, ceramics, plastics and other materials, so that the substrate has a waterproof and oilproof fingerprint performance, its surface tension is very small, can be instantly levelled.UF-310 has a high abrasion resistance and high smooth, and has excellent UV irradiation resistance properties.

Physical property:

| appearances | Colourless transparent liquid |

| principal component | Perfluoropolyether derivatives |

| density | 1.45 g/mL |

| fluids | hydrofluoric ether |

| solid | 20wt% |

Product Performance:

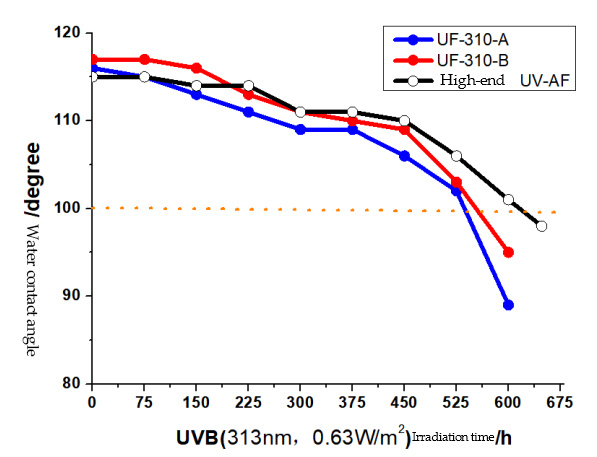

Characteristics of UF-310 and corresponding performance indicators

| Specificities | Corresponding performance indicators |

| Excellent resistance to UV irradiation | 1.UVB(313nm), 0.63W/m2 irradiation, UF-310 can maintain about 600h, ordinary AF only maintain about 72h; 2.SAE J2527: UF-310 can pass the test of about 1000h, ordinary AF only about 200h. |

| Better acid resistance | 1wt% HCl, 25°C, 4 days, water contact angle around 115°. |

| Better alkali resistance | 5wt% Na2CO3, 25°C, 24 hours, water contact angle >100° |

Performance comparison between UF-310 and UV-resistant AF competitors

Areas of application:

1) Automotive field, such as car display, windscreen, etc;

2) Eyeglasses, outdoor cameras, glass curtain walls, etc;

3) Other AF substrates in outdoor use scenarios.

Product Features:

- Anti-fingerprint, waterproof, anti-oil, anti-dirt, good smoothness;

- Simple and convenient operation, surface dry curing at room temperature, good economy;

- Excellent adhesion and abrasion resistance;

- Nano level transparent coating, very high transmittance rate, does not affect the appearance of the product;

- Safe, environmentally friendly, non-toxic, non-toxic to human body.

Shelf life and storage methods:

- Shelf life 6 months when stored at room temperature away from light.

- Shelf life: 1 month after mixing with diluent and storing at room temperature.

(Ⅲ)No-Bake Anti-fingerprint Liquid

Product Description:

No-bake anti-fingerprint liquid is a self-drying, no-bake hydrophobic and oleophobic nano-fingerprint oil, colourless, odourless and transparent liquid, suitable for high alumina silicon glass, mobile phone glass cover, glass protection stickers, electronic displays, optical lenses, and the surface of the metal substrate anti-fouling anti-fingerprint treatment. After treatment, the surface of the substrate forms a complete protective film of waterproof, anti-fouling and anti-fingerprints, with excellent adhesion, very low surface tension, excellent hydrophobicity and oleophobicity, anti-fingerprints, easy to wipe, and high smoothness. At present, the company has three models: MK-012, MK-013, MK-014, steel wool abrasion resistance ranging from 3000-10000 times.

No Bake Fingerprint Resistant Original Features

- Anti-fingerprint, waterproof, anti-oil, anti-dirt, good smoothness;

- Simple and convenient operation, surface dry curing at room temperature, good economy;

- Excellent adhesion and abrasion resistance;

- Nano level transparent coating, very high transmittance rate, does not affect the appearance of the product;

- Safe, environmentally friendly, non-toxic, non-toxic to human body.

Application process:

Formulation of no-bake anti-fingerprint spray solution: the original liquid accounted for the proportion of diluent in the 3-5 wt ‰, and then fully stirred until the solution becomes homogeneous. According to different performance needs to formulate the corresponding proportion.

Application example (MK-014, 3.0 wt‰)

- Substrate: Glass sheet;

- Coating: plasma spray;

- Initial drop angle: 5min at room temperature, drop angle 116-119°; 4h at room temperature, drop angle 116-119°;

- Abrasion resistance: load 1kg, BONSTAR#0000 steel wool, area 1cm×1cm, water droplet angle >105° after 10,000 times of back and forth rubbing;

- Dynamic friction coefficient: 0.03±0.005.

Contact Us

Floor 2, Building F, Kechuang Park, Free Trade Zone, No.36 Huada Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Copyright©️ 2024 Suzhou Dongxing New Material Technology Co., Ltd. All Rights Reserved

SEO | Business License Powered by:300.cn