Machining center

AF Coating

Click to expand +

Product Overview:

AF (Anti-Fingerprint) processing uses dry or wet techniques to create an ultrathin anti-fingerprint coating on the material surface, effectively preventing fingerprint residue while maintaining a smooth, easy-to-clean surface. Depending on the process, PVD (Physical Vapor Deposition), spray coating, and dip coating can be chosen.

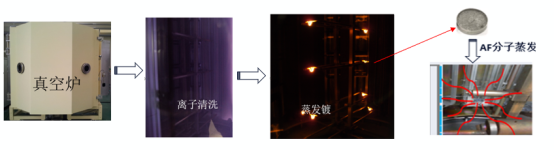

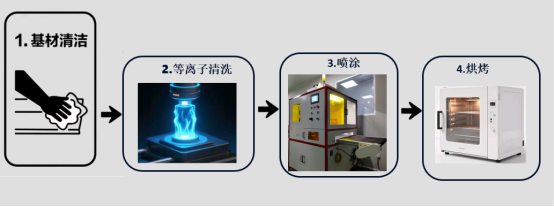

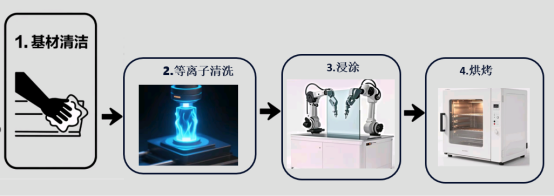

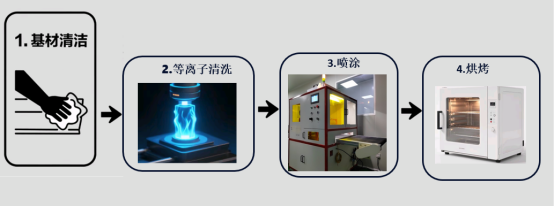

Process Description:

(1) PVD Processing: In a high-vacuum environment, the source material is volatilized using electron gun heating or resistive evaporation heating, etc., forming particles such as atoms, molecules, or ions. These particles combine with the substrate through physical/chemical reactions to form a uniform nanometer-thin film.

(2) Spray Coating: The AF functional liquid is dispersed into uniform and fine mist droplets by a spraying device and applied to the substrate surface. It is then processed at a certain temperature to form a uniform nano-coating.

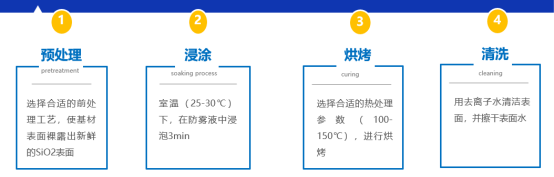

(3) Dip Coating: The substrate is immersed in the AF functional liquid for a certain time, allowing the substrate surface to adhere to a certain amount of AF functional liquid. It is then processed at a certain temperature to form a uniform nano-coating.

Characteristics:

Excellent hydrophobic and oleophobic properties: The AF coating has good water and oil resistance, reducing the adhesion of stains on the substrate surface and making maintenance convenient.

Strong wear resistance: The AF coating has strong adhesion to the substrate, is wear-resistant, and has a long service life.

Good chemical stability: The AF molecular chemical bond energy is high, making it difficult to decompose and resistant to corrosion from common chemicals.

Good smoothness: The AF coating has a low dynamic coefficient of friction, improving the smooth touch feeling of the substrate surface.

Application Areas:

AF technology is widely used in the following areas: electronic displays of electronic products such as smartphones, tablets, and televisions; various camera lenses; car windows, building glass; and metal surfaces, etc. By reducing fingerprint residue, it improves visual experience and durability, making it an indispensable key technology in modern production.

PVD is suitable for small-sized components with high appearance requirements and irregular shapes.

Spray coating is suitable for large-sized planar components.

Dip coating is suitable for larger components with irregular shapes.

Other related images:

Antibacterial AF Coating Processing

Click to expand +

Product Overview:

We have integrated antibacterial technology and AF technology, which not only effectively prevents fingerprint residue but also inhibits the growth of bacteria on the material surface, improving the product's hygiene and safety performance.

Process Description:

Characteristics:

Excellent hydrophobic and oleophobic properties: The AF coating has good water and oil resistance, reducing the adhesion of stains on the substrate surface and making maintenance convenient.

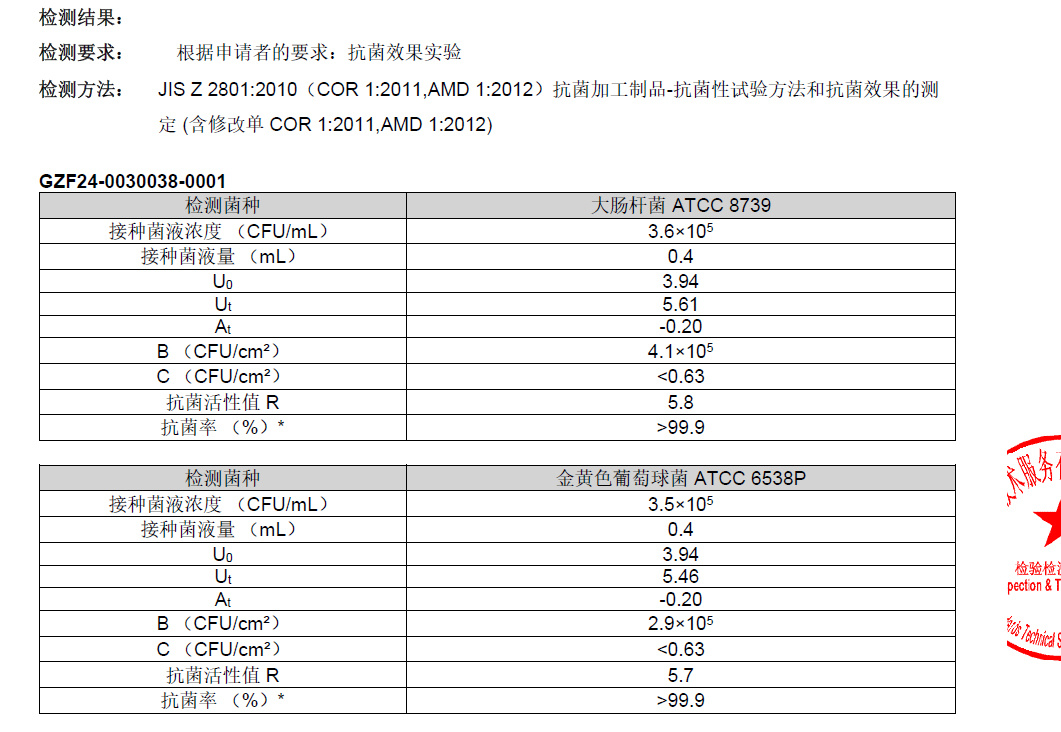

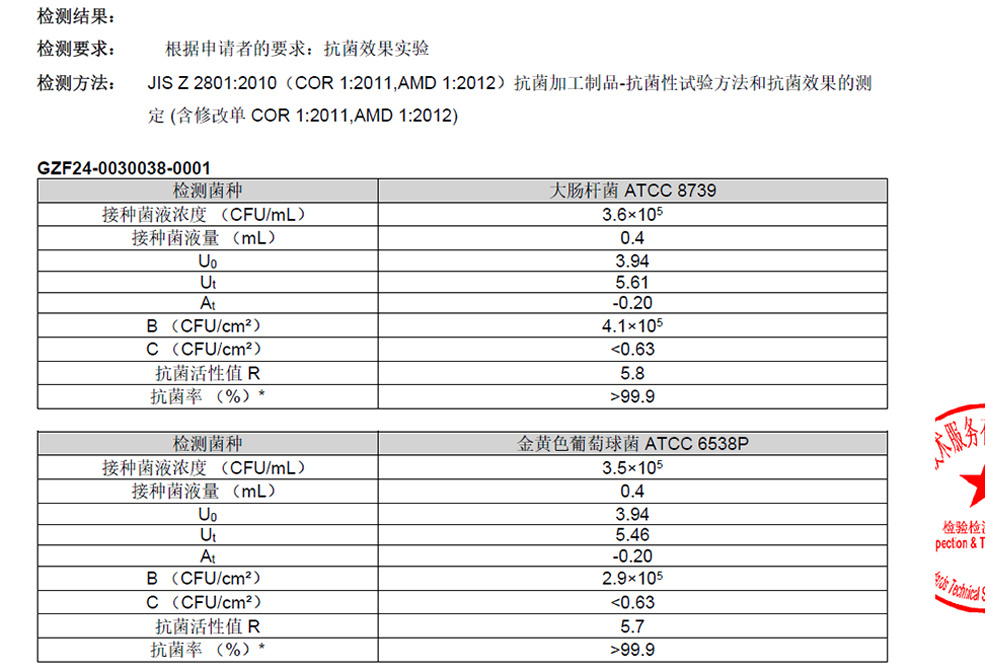

Excellent antibacterial performance: Effectively resists the invasion of various microorganisms, with a bacterial kill rate exceeding 99.9%.

Good weather resistance and chemical resistance: The AF molecular chemical bond energy is high, making it difficult to decompose and resistant to corrosion from common chemicals.

Application Areas:

Antibacterial and anti-fingerprint products are widely used in mobile phones, computers, touch panels, medical equipment, new energy vehicle interiors, and daily necessities. Effectively protecting user health while improving overall product quality and user experience, leading a new trend in healthy living.

Other related images:

Antibacterial and antiviral AF processing

Click to expand +

Product Overview:

We have integrated AF technology and antibacterial and antiviral technology, which not only effectively prevents fingerprint residue but also inhibits the growth of bacteria and viruses on the material surface, improving the product's hygiene and safety performance.

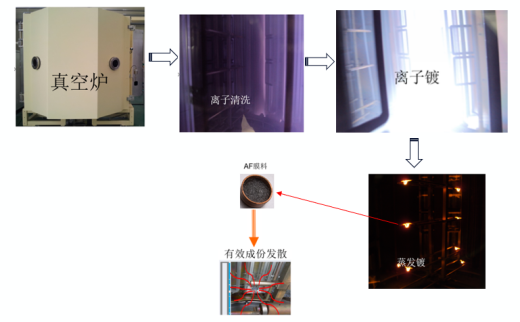

Process Description:

Active composite inorganic nano-ions generated using magnetron sputtering technology exhibit excellent antibacterial and antiviral effects, providing strong protection for public health and safety. A nano-anti-fingerprint coating is formed using evaporation heating technology, providing excellent anti-fingerprint characteristics.

Characteristics:

High-efficiency antibacterial: Antibacterial rate up to 99.9%.

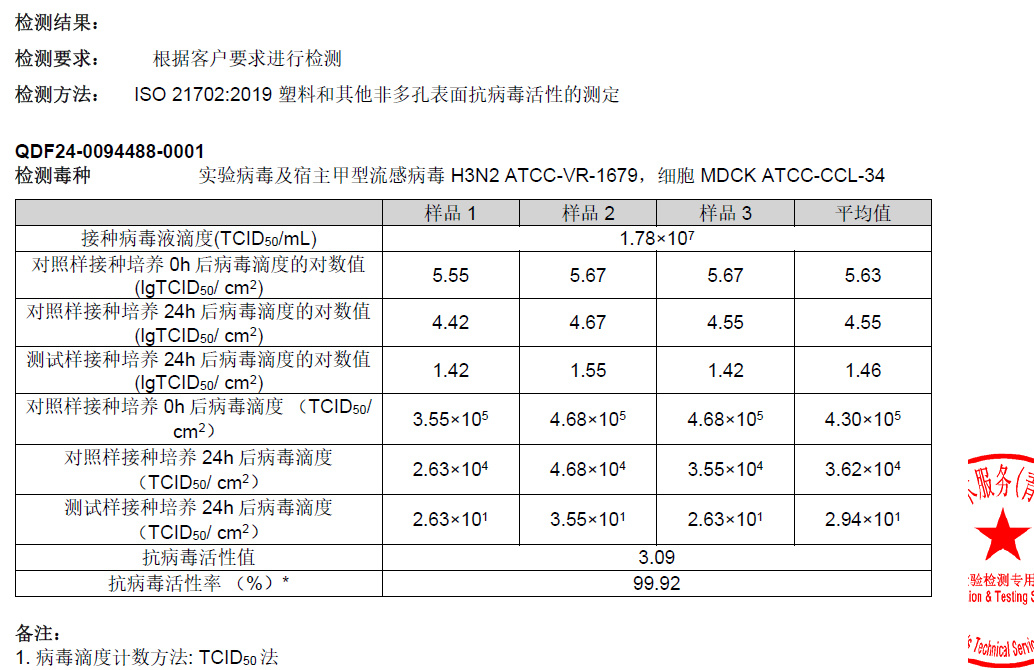

Wide-ranging antiviral: Antiviral activity reaches 99.9%.

Water and oil resistant, easy to clean: Good water and oil resistance, effectively protecting against stains.

Long-lasting effect, long-term protection.

Multi-scenario application: Can be widely applied to various material surfaces.

Application Areas:

Mobile phones and tablet screens, etc., daily high-frequency contact devices; elevator buttons and door handles, etc., high-frequency contact parts in public places; home appliance panels; car interiors such as steering wheels, touch screens, etc., key parts; self-service terminals in public places such as banks and supermarkets; shared equipment such as shared screens and shared keyboards.

Other materials:

| Performance | DX Antibacterial, Antiviral, and Anti-fingerprint Product | Ordinary Anti-fingerprint Product |

| Light Transmittance | ≥92% | ≥92% |

| Initial Water Contact Angle | ≥115° | ≥115° |

| Abrasion Resistance* Times | ≥5000 times | ≥5000 times |

| Antibacterial Rate | ≥99.9% | <50% |

| Antiviral Activity Rate | ≥99.9% | <50% |

| *0000# steel wool friction head, 1*1cm, 1000g load, 40cm stroke, 60 times/minute, water contact angle >100° after grinding | ||

Anti-fog Processing

Click to expand +

Product Overview:

An ultra-hydrophilic coating is formed on the material surface through dip coating, which can effectively prevent water vapor from condensing into droplets, keeping the vision clear.

Principle Introduction:

Under normal circumstances, condensed water will condense into a layer of fine water droplets adhering to the transparent interface. Light is scattered and irregularly refracted at the water droplet interface, resulting in blurred visual imaging, which is “fogging”. On the ultra-hydrophilic interface, however, condensed water will automatically spread into a uniform, thin water film, allowing light to pass through along the same refractive path without affecting visual imaging.

Process Description:

By immersing the substrate in the anti-fogging liquid for a certain period of time, a certain amount of anti-fogging liquid is attached to the surface of the substrate, and then processed at a certain temperature to form a uniform nano-anti-fogging coating.

Characteristics:

| Sequence | Test Item | Test Condition | Water Contact Angle After Test | Anti-fogging Grade After Test | Hardness Grade After Test | Adhesion After Test |

| 1 | Initial Water Contact Angle | Original Film Water Contact Angle | <5° | Grade 1 | / | / |

| 2 | Alcohol Rubbing Test | 75% alcohol, 500g pressure, 15000 reciprocating times, speed 40/min, stroke 4cm, 1*1 dust-free cloth | 7.122° | Grade 1 | / | / |

| 3 | Adhesion Test | Use a cross-hatch cutter (1cm wide, 1mm spacing between teeth) to make cross-hatch marks, then adhere 3M tape to the marked surface, press lightly with your fingers until fully adhered, and then quickly peel off the tape at a 90° angle. | / | / | / | OK |

| 4 | Dust-free Cloth Dry Rubbing | 4000 reciprocating times under 500g pressure, speed 40/min, stroke 4cm, 1*1 dust-free cloth abrasion resistance | 5.877° | Grade 1 | / | / |

| 5 | Dust-free Cloth Wet Rubbing | 3000 reciprocating times under 500g pressure, speed 40/min, stroke 4cm, 1*1 dust-free cloth wet abrasion resistance (pure water) | 5.023° | Grade 1 | / | / |

| 6 | High Temperature Resistance Test | Stored in a 75℃ high-temperature oven for 3 hours | <5° | Grade 1 | / | / |

| 7 | Low Temperature Resistance Test | Stored in a freezer at -15℃ for 30 minutes and then taken out | <5° | Grade 1 | / | / |

| 8 | Immersion (Acid) | Acid value = 3, immersed for 30min | 11.544 | Grade 2 | / | / |

| 9 | EF74 Rubber Test | 4000 reciprocating times under 1000g pressure, speed 40/min, stroke 4cm | <5° | Grade 1 | / | / |

| 10 | 85/85 Test | Stored at 85℃ temperature and 85% humidity for 48 hours | <5° | Grade 2 | / | / |

| 11 | UV Resistance Test | Placed in a UV box for 48 hours | <5° | Grade 2 | / | / |

Application Scenarios:

Widely used in daily consumer products such as swimming goggles, ski goggles, protective goggles, and bathroom mirrors; electronic equipment that requires a clear field of vision, such as security cameras and lidar covers; parts of automobiles such as windshields, side windows, and rearview mirrors; and building materials such as building windows and curtain walls to ensure a clear field of vision in extreme environments.

Other materials:

Superhydrophobic Processing

Click to expand +

Product Overview:

A superhydrophobic coating is formed on the surface of the material by spraying, making the contact angle of the material surface greater than 150° and the rolling contact angle less than 10°.

Principle Introduction:

The material surface is composed of a special surface micro-nano rough structure and low surface energy chemical substances, making the water contact angle of the material surface greater than 150°.

Process Description:

The superhydrophobic coating is dispersed into uniform and fine droplets by a specific device (such as a spray gun or disc atomizer) and applied to the surface of the substrate. It is then processed at a certain temperature to form a uniform nano-coating.

Characteristics:

Water contact angle > 150°;

Rolling contact angle < 10°;

Good impact resistance;

High hardness;

Long service life.

Application Scenarios:

Superhydrophobic products have a wide range of applications in many fields, including but not limited to outdoor antennas (snow prevention), ocean-going vessels (anti-fouling, anti-corrosion), oil pipeline transportation, microneedle tips (eliminating drug adhesion), waterproof and antifouling treatment, etc.; In the medical field, superhydrophobic materials are used to inhibit bacterial growth and prevent wound infection and ulceration; In the construction field, superhydrophobic materials are used for wall protection, reducing labor cleaning costs and energy consumption; In the military field, superhydrophobic materials provide weapons with comprehensive protection such as wear resistance and anti-fogging.

Other materials:

Contact Us

Floor 2, Building F, Kechuang Park, Free Trade Zone, No.36 Huada Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Copyright©️ 2024 Suzhou Dongxing New Material Technology Co., Ltd. All Rights Reserved

SEO | Business License Powered by:300.cn